Jensen TV manuals are comprehensive guides offering detailed setup‚ troubleshooting‚ and maintenance instructions․ Available as downloadable PDFs‚ they ensure optimal performance for various Jensen TV models‚ including LED and smart TVs․

1․1 Overview of Jensen TV Models

Jensen offers a range of TV models‚ including LED TVs like the JE3214‚ JE5020‚ and 14 SERIES‚ featuring HD resolution and smart TV capabilities․ These models vary in size and functionality‚ catering to different viewer preferences․ Manuals for these devices provide detailed specifications‚ ensuring users can maximize their viewing experience․ Whether you own a JE1914 or a JTV2815DC‚ Jensen’s manuals are tailored to each model’s unique features and settings․

1․2 Importance of Reading the Manual

Reading the Jensen TV manual is essential for understanding safety precautions‚ setup‚ and troubleshooting․ It provides detailed instructions for optimal performance‚ helping users navigate features‚ connect devices‚ and resolve common issues․ The manual also covers maintenance tips to extend the TV’s lifespan․ By following the guidelines‚ users can ensure proper installation‚ configuration‚ and operation of their Jensen TV‚ enhancing their overall viewing experience and preventing potential damage․

Safety Precautions

Always follow safety guidelines to avoid hazards․ Ensure proper ventilation‚ avoid liquid exposure‚ and handle the TV with care to prevent damage or injury․

2․1 Handling the TV Safely

Always handle your Jensen TV with care to prevent damage and ensure safety․ Carefully unpack the TV‚ avoiding direct contact with the screen to prevent smudging․ Use two people to lift larger models due to weight․ Never touch the screen excessively‚ as oils from skin can cause damage․ Clean the screen with a soft‚ dry cloth if necessary․ Avoid placing heavy objects on the TV or standing it upright improperly․ Keep children away from handling the TV unsupervised․

2․2 Electrical Safety Tips

Ensure your Jensen TV is plugged into a grounded power outlet to prevent electrical shocks․ Avoid exposing the TV to water or moisture‚ as this can cause malfunctions or safety hazards․ Never use damaged power cords or electrical accessories‚ as they may lead to fire risks․ Keep the TV away from direct sunlight or heat sources to prevent overheating․ Always unplug the TV during thunderstorms or when not in use for extended periods․ Use a surge protector to safeguard against voltage spikes․

2․3 Environmental Precautions

Dispose of your Jensen TV and accessories responsibly‚ adhering to local regulations for electronic waste․ Avoid exposing the TV to extreme temperatures‚ humidity‚ or direct sunlight‚ as this may damage internal components; Prevent physical stress or shocks to the device․ Clean the screen and exterior with approved products to maintain performance․ Follow eco-friendly guidelines for recycling batteries and packaging materials․ Proper handling ensures longevity and environmental safety․

Remote Control Setup

The dual-function remote control simplifies operation․ Pair it with your Jensen TV for seamless navigation․ Use it to control power‚ volume‚ and other connected devices effortlessly․

3․1 Pairing the Remote with the TV

To pair the remote with your Jensen TV‚ ensure both devices are powered on․ Press and hold the TV button on the remote until the LED blinks․ Enter the three-digit manufacturer code from the manual․ The remote will sync automatically once the correct code is entered‚ enabling full control over your TV’s functions․ This process ensures a seamless connection for optimal performance․

3․2 Programming the Remote for Other Devices

Programming the remote for other devices like DVD players or soundbars involves entering specific codes․ Turn on the device‚ press and hold the remote’s TV button until the LED blinks․ Enter the three-digit code for your device from the manual․ Release the button and test functionality․ If it doesn’t work‚ repeat with an alternate code․ This feature allows seamless control of multiple devices‚ enhancing your viewing experience․ Refer to the manual for a full list of compatible codes․

Initial Setup and Installation

Unpacking and installing your Jensen TV involves careful handling and placement․ Connect peripheral devices according to the manual for a seamless setup experience․

4․1 Unpacking and Physical Installation

Begin by carefully unpacking your Jensen TV‚ ensuring all components are included․ Handle the screen with care to avoid damage․ Place the TV on a stable surface or wall mount‚ adhering to VESA standards for secure installation․ Read safety precautions before proceeding․ Connect all cables neatly and ensure proper ventilation․ Avoid exposing the TV to moisture or extreme temperatures․ Follow the manual’s guidelines for electrical connections and mounting options to ensure optimal performance and longevity․

4․2 ConnectingPeripheral Devices

4․2 Connecting Peripheral Devices

Connect peripheral devices such as DVD players‚ gaming consoles‚ or sound systems using HDMI or component inputs․ Ensure cables are securely plugged into the correct ports on the TV․ For HDMI connections‚ use high-quality cables to maintain video and audio quality․ Refer to the TV’s input menu to select the appropriate source․ Power on devices after connection to ensure proper recognition․ Follow the manual’s guidelines for configuring audio outputs and ensuring compatibility with connected devices for optimal performance․

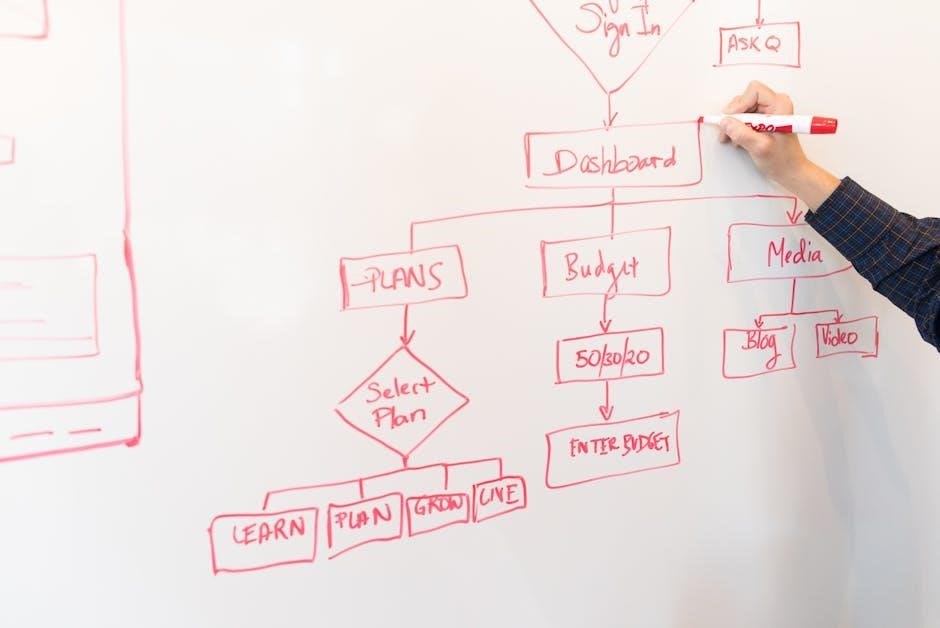

Navigating the TV Menu

Access the menu using the remote control’s menu button․ Navigate options using arrow keys and select settings with OK/Enter․ Customize viewing preferences efficiently․

5․1 Accessing and Understanding Menu Options

Press the MENU button on the remote to access the TV menu․ Use arrow keys to navigate through options like Picture‚ Sound‚ and Settings․ Highlight desired options with arrow keys and select using OK/Enter․ Sub-menus appear for detailed adjustments‚ such as brightness or audio modes․ On-screen descriptions guide you through each setting‚ ensuring easy customization for optimal viewing experiences․

5․2 Customizing Settings for Optimal Viewing

Adjust picture settings like brightness‚ contrast‚ and color to suit your viewing environment․ Select predefined modes such as Movie or Sports for enhanced clarity․ Fine-tune sound settings‚ including equalizer options‚ to optimize audio quality․ Enable features like motion interpolation or noise reduction for smoother visuals․ Customize input labels for connected devices and set up parental controls for added convenience․ Experiment with these options to achieve your preferred viewing experience․

Troubleshooting Common Issues

Identify and resolve connectivity‚ picture‚ and sound problems by checking cables‚ restarting the TV‚ or adjusting settings; Refer to the manual for detailed diagnostic steps․

6․1 Diagnosing and Resolving Connectivity Problems

Connectivity issues‚ such as HDMI problems or Wi-Fi disconnects‚ can disrupt your viewing experience․ Start by checking all cables for secure connections and ensuring they are undamaged․ Restart both the TV and connected devices to reset the connection․ For wireless issues‚ verify network stability and ensure the TV is connected to the correct Wi-Fi network․ If problems persist‚ consult the manual for advanced troubleshooting steps or reset network settings to default․

6․2 Addressing Picture and Sound Issues

Picture and sound issues can affect your viewing experience․ Check volume settings and ensure mute is off․ Verify HDMI connections are secure and select the correct input․ Adjust display settings like brightness and contrast for optimal clarity․ For sound‚ ensure speakers are enabled and configured correctly․ Reset picture settings to default if needed․ If issues persist‚ consult the manual for advanced troubleshooting or reset audio/video settings to restore proper functionality․

Software and Firmware Updates

Regular software and firmware updates ensure optimal TV performance‚ security‚ and feature enhancements․ Check for updates in the settings menu and install them to maintain peak functionality․

7․1 Checking for Updates

To ensure your Jensen TV operates at its best‚ regularly check for software and firmware updates․ Navigate to the TV’s settings menu‚ typically found under “System” or “About This TV․” Select “Check for Updates” to initiate the process․ If an update is available‚ the TV will automatically download and install it․ This ensures improved performance‚ security patches‚ and new features․ For manual updates‚ visit the official Jensen website and follow the provided instructions for your specific model․ Regular updates are crucial for optimal functionality and enhanced viewing experiences․

7․2 Installing Updates Manually

To manually install updates on your Jensen TV‚ download the latest firmware from the official Jensen website․ Ensure the file is compatible with your TV model․ Transfer the update file to a USB drive‚ formatted to FAT32․ Access the TV settings‚ navigate to the “System” or “Maintenance” section‚ and select “Update” or “Manual Update․” Insert the USB drive‚ follow on-screen instructions‚ and wait for the installation to complete․ Always turn off the TV before starting the update process․ Consult the user manual for specific model instructions․

Audio and Video Connections

This section explains how to connect external devices using HDMI and component inputs․ It also guides setting up audio outputs for optimal sound quality and device compatibility․

8․1 Using HDMI and Component Inputs

Connect external devices like DVD players or gaming consoles using HDMI for high-definition video and audio․ Component inputs support analog video and audio connections․ Ensure cables are securely plugged into the correct ports on the TV․ HDMI provides superior quality‚ while component inputs are ideal for older devices․ Refer to the manual for specific port locations and compatibility․ Troubleshoot common issues like no signal by checking cable connections and input selection․

8․2 Setting Up Audio Outputs

Configure audio outputs to enhance your viewing experience․ Use HDMI ARC for seamless soundbar or home theater connections․ Optical and RCA outputs are available for older audio systems․ Ensure correct settings in the TV menu‚ selecting the appropriate audio format․ Test the connection by playing content․ Refer to the manual for specific setup instructions and troubleshooting tips to achieve optimal sound quality․

VESA Mounting Pattern

Jensen TVs feature a VESA 200mm x 200mm mounting pattern‚ ensuring compatibility with standard wall mounts․ Ensure the mount supports the TV’s weight for secure installation․

9․1 Understanding the Mounting Options

Jensen TVs support the VESA 200mm x 200mm mounting pattern‚ ensuring compatibility with most wall mounts․ This standard allows for secure installation‚ whether using fixed‚ tilt‚ or full-motion mounts․ Always verify the mount’s weight capacity matches your TV’s specifications․ Additional hardware may be required for certain setups․ Follow the manufacturer’s instructions for proper installation to ensure stability and safety․ Consult your TV’s manual or contact Jensen support for specific mounting recommendations tailored to your model․

Maintenance and Care

Regularly clean the screen with a soft cloth and avoid harsh chemicals․ Dust the exterior gently and ensure proper ventilation for optimal performance and longevity․

10․1 Cleaning the Screen and Exterior

Regular cleaning is essential for maintaining your Jensen TV’s performance and longevity․ Use a soft‚ dry microfiber cloth to gently wipe the screen and exterior surfaces․ For tougher smudges‚ lightly dampen the cloth with distilled water‚ but avoid moisture entering vents or ports․ Never use harsh chemicals‚ abrasive materials‚ or paper towels‚ as they may damage the screen․ For the exterior‚ a soft‚ dry cloth suffices․ Cleaning ensures optimal picture quality and prevents dust buildup that could affect cooling and performance․

10․2 Regular Maintenance Tips

Regular maintenance ensures your Jensen TV functions optimally․ Update the software periodically to access new features and security patches․ Check all HDMI and audio connections for stability․ Power cycle the TV monthly to clear cached data and resolve minor glitches․ Dust the vents regularly to prevent overheating and ensure proper airflow․ Use a surge protector to safeguard against power fluctuations‚ maintaining consistent performance and extending the TV’s lifespan․

Downloading the Manual

Visit Jensen’s official website to download your TV’s manual․ Enter your model number to find the correct PDF guide‚ ensuring proper setup and troubleshooting assistance․

11․1 Finding the Correct Manual for Your Model

To find the correct manual for your Jensen TV‚ visit the official Jensen website and navigate to the support section․ Enter your TV’s model number in the search bar to locate the corresponding PDF manual․ Ensure the model number matches exactly to download the right guide․ If unsure‚ refer to the label on your TV or its packaging for accurate model identification․ This ensures you access precise instructions tailored to your device‚ optimizing setup and troubleshooting efficiency․